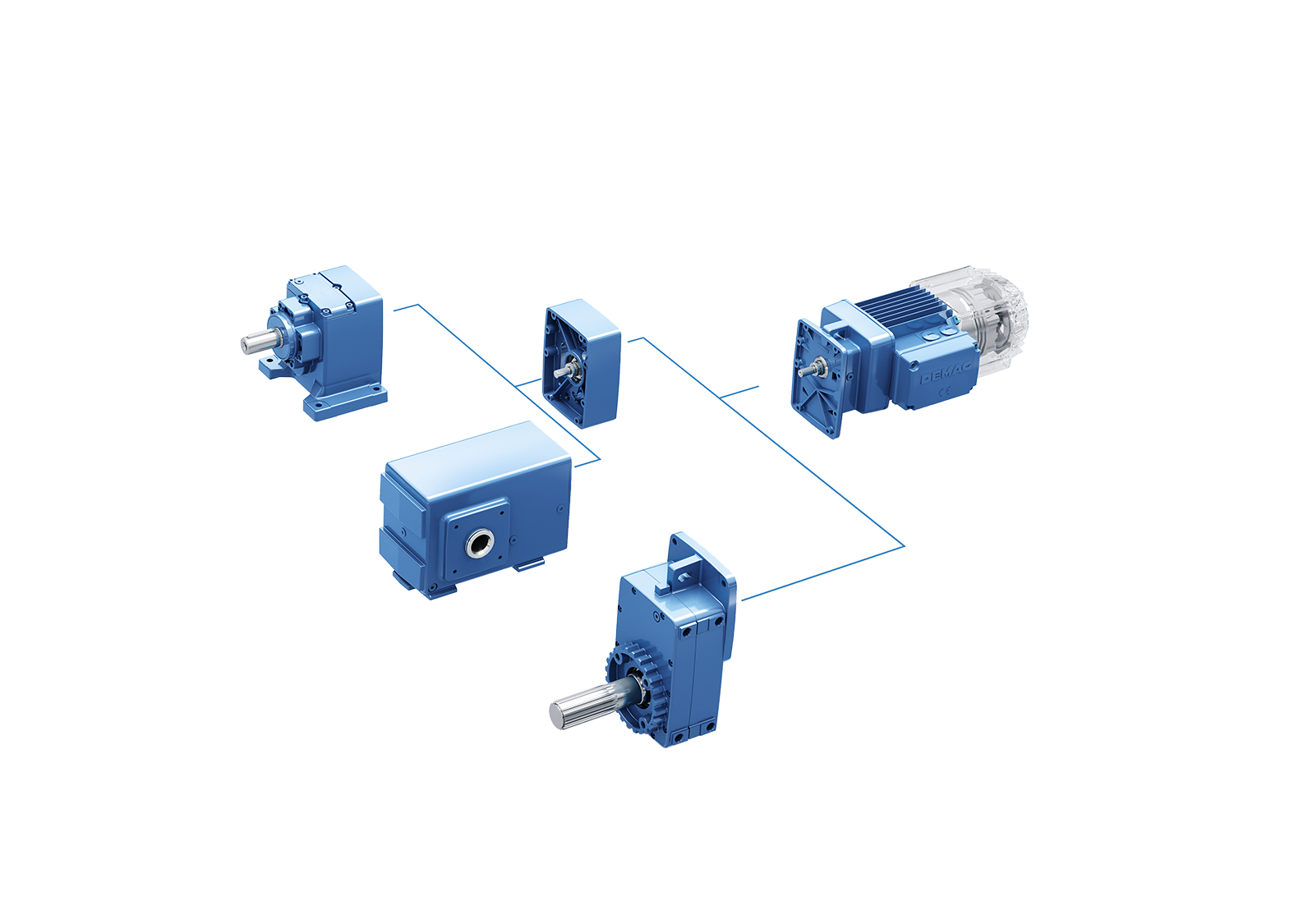

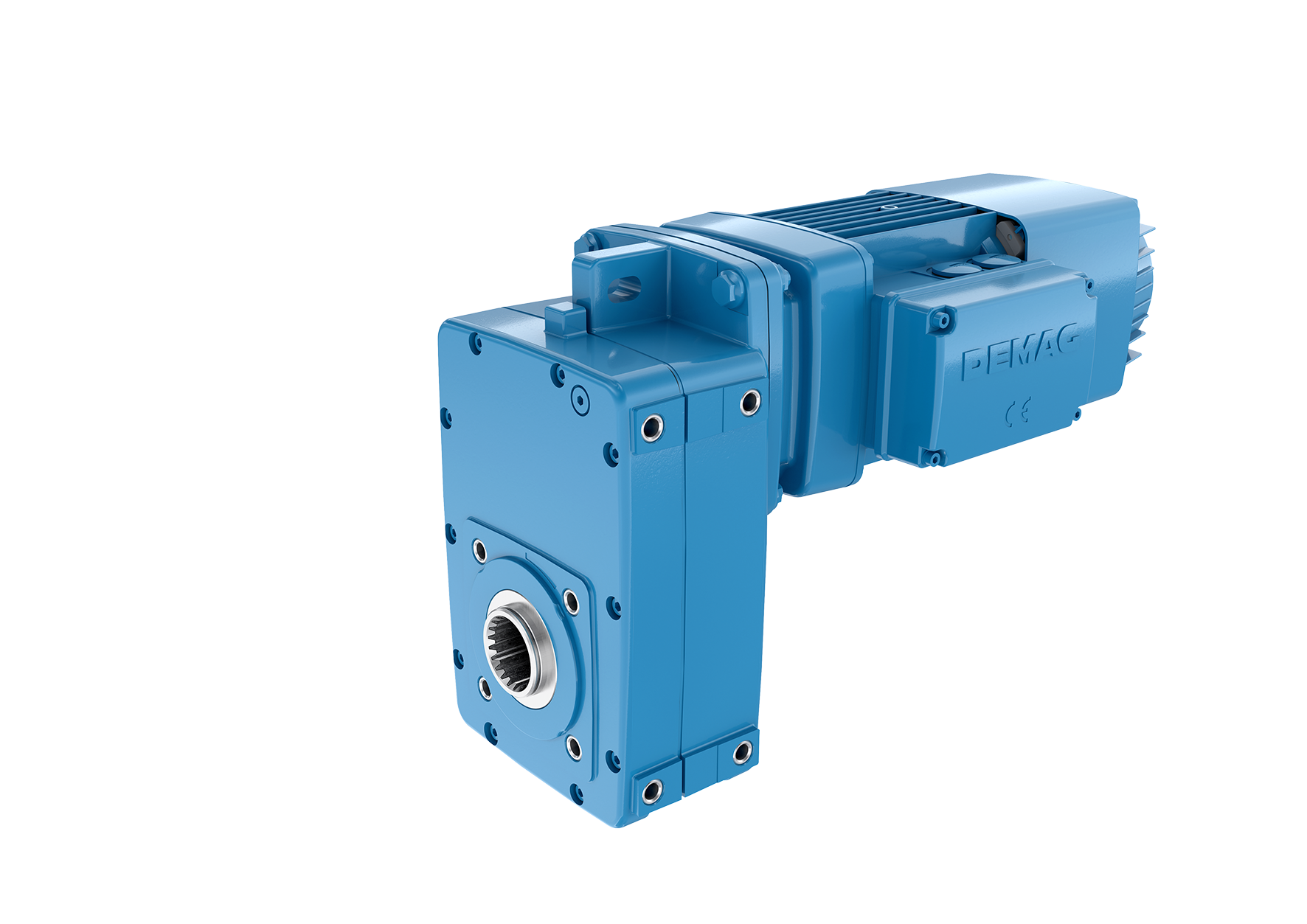

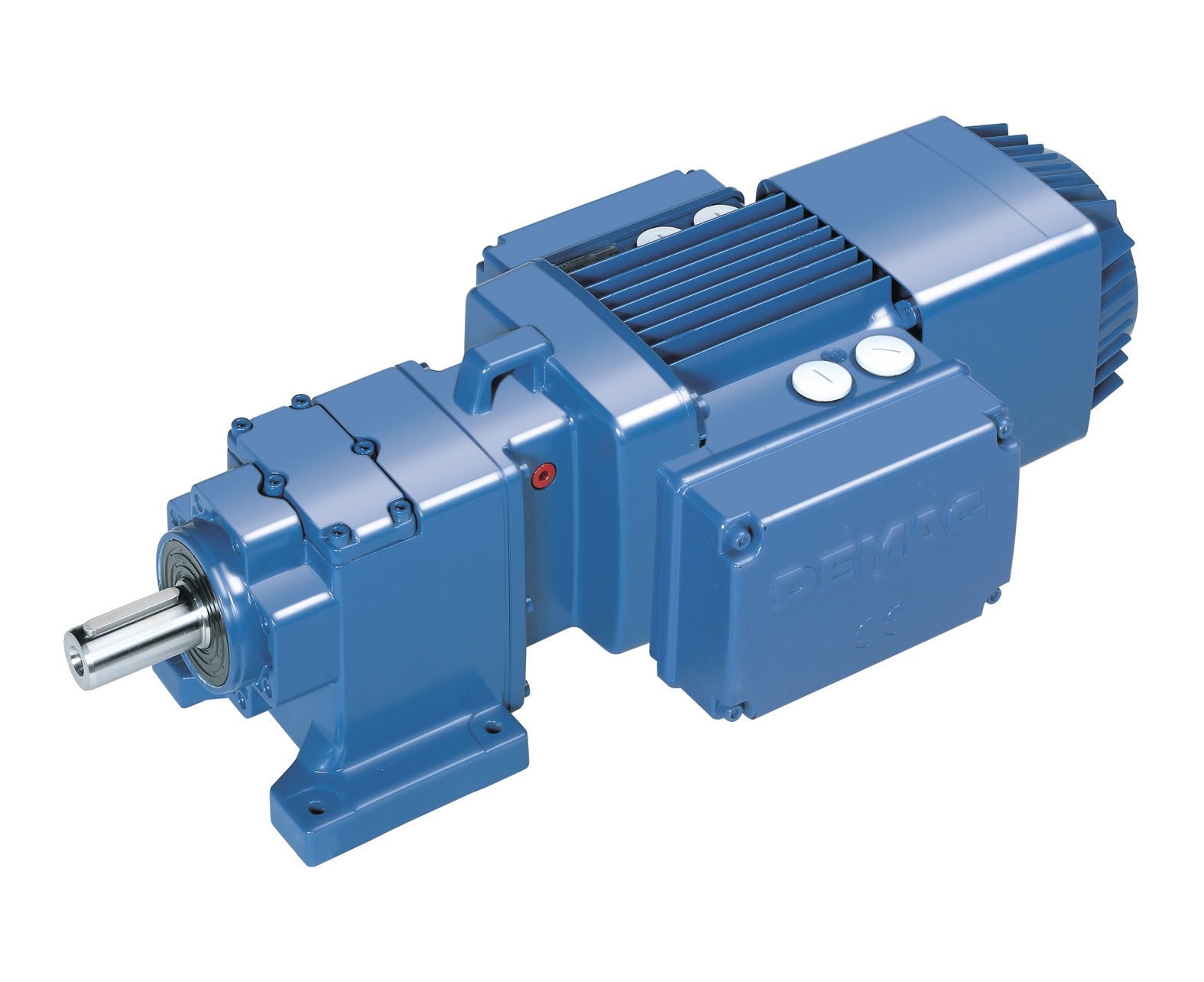

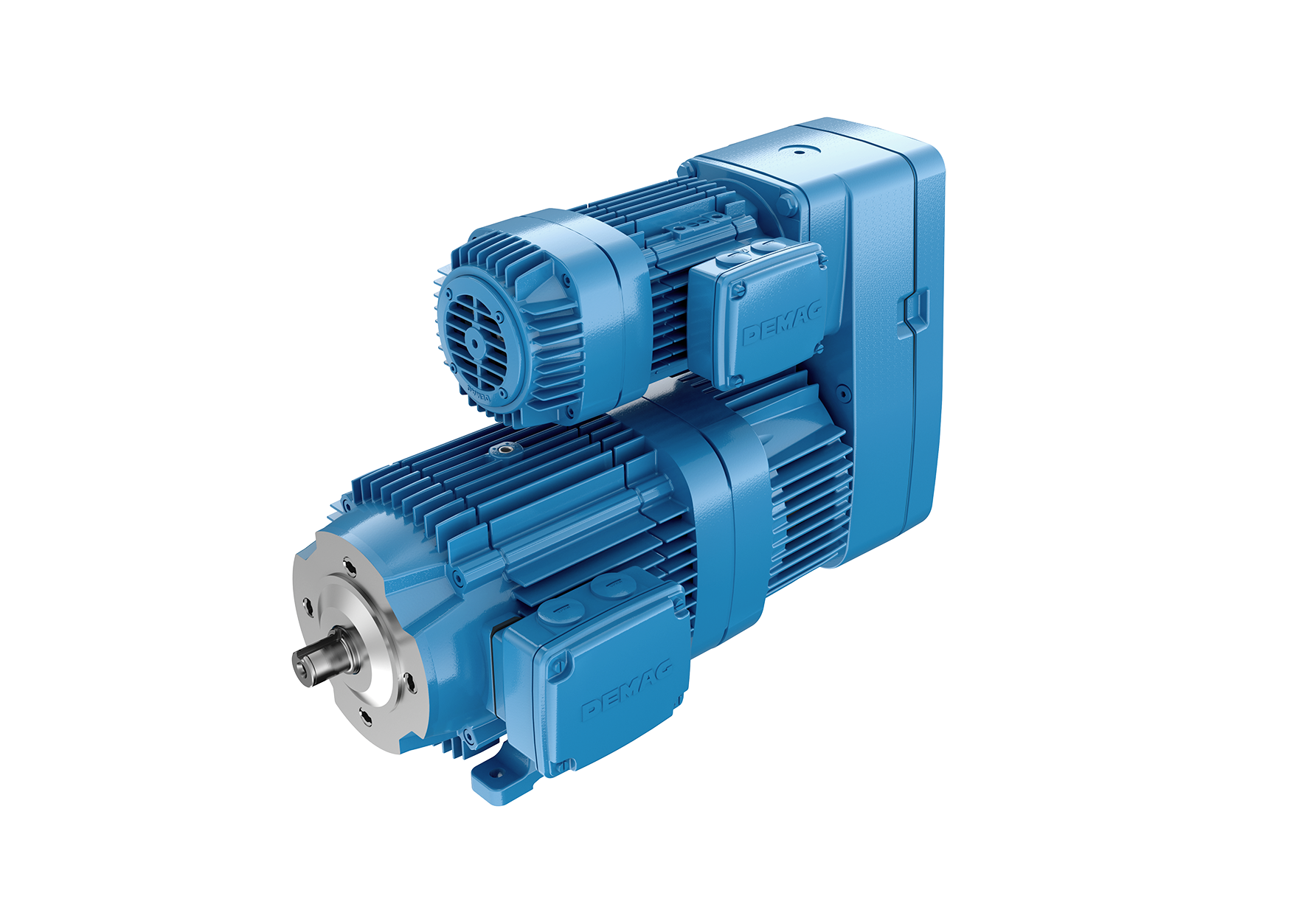

Our geared motors are configured from a modular range of motors and gearboxes that are designed for a perfect match. Our modular system enables us to implement solutions tailored to meet your needs quickly and cost-effectively using standardized sub-assemblies to create offset geared motors, angular geared motors and helical geared motors.

This saves you valuable project engineering time – and gives you the certainty of reliable specification. At the same time, you benefit from our extensive design and application expertise in every module.