| Stacker trolley selection table | Stacker trolley crane data | ||||||||

| Lifted load | b | Size | H | T | KBK | lHT | lKr | lW KBK II-L | lW KBK II |

| [kg] | [mm] | [mm] | [mm] | [mm] | [mm] | [mm] | [mm] | ||

| 80 | 900 | 2 | 4,110 | 3,420 | II-L | 5,000 | 4,500 | 4,000 | 6,000 |

| II | 6,000 | 5,500 | 3,500 | 6,000 | |||||

| 1200 | 3 | 5,110 | 4,420 | II-L | 5,000 | 4,500 | 3,000 | 5,000 | |

| II | 6,000 | 5,500 | 3,000 | 5,000 | |||||

| 100 | 800 | 2 | 4,110 | 3,420 | II-L | 5,000 | 4,500 | 3,500 | 6,000 |

| II | 6,000 | 5,500 | 3,500 | 5,500 | |||||

| 1000 | 3 | 5,110 | 4,420 | II-L | 5,000 | 4,500 | 3,000 | 5,000 | |

| II | 6,000 | 5,500 | 3,000 | 4,500 | |||||

| 125 | 700 | 2 | 4,110 | 3,420 | II-L | 5,000 | 4,500 | 3,500 | 5,500 |

| II | 6,000 | 5,500 | 3,500 | 5,500 | |||||

| 900 | 3 | 5,110 | 4,420 | II-L | 5,000 | 4,500 | 3,000 | 4,500 | |

| II | 6,000 | 5,500 | 3,000 | 4,500 | |||||

| 160 | 550 | 2 | 4,110 | 3,420 | II-L | 5,000 | 4,500 | 3,000 | 5,000 |

| II | 6,000 | 5,500 | 3,000 | 5,000 | |||||

| 800 | 3 | 5,110 | 4,420 | II-L | 5,000 | 4,500 | 2,500 | 4,000 | |

| II | 6,000 | 5,500 | 2,500 | 4,000 | |||||

| 200 | 480 | 2 | 4,110 | 3,420 | II-L | 5,000 | 4,500 | 2,500 | 4,500 |

| II | 6,000 | 5,500 | 2,500 | 4,500 | |||||

| 650 | 3 | 5,110 | 4,420 | II-L | 5,000 | 4,500 | 2,000 | 4,000 | |

| II | 6,000 | 5,500 | 2,000 | 4,000 | |||||

| 250 | 400 | 2 | 4,110 | 3,420 | II-L | 5,000 | 4,500 | 2,500 | 4,500 |

| II | 6,000 | 5,500 | 2,500 | 4,000 | |||||

| 600 | 3 | 5,110 | 4,420 | II-L | 5,000 | 4,500 | 2,000 | 4,000 | |

| II | 6,000 | 5,500 | 2,000 | 3,500 | |||||

| 315 | 370 | 2 | 4,110 | 3,420 | II-L | 4,500 | 4,000 | 2,000 | 4,000 |

| II | 5,000 | 4,500 | 2,000 | 3,500 | |||||

| 600 | 3 | 5,110 | 4,150 | II-L | 4,500 | 4,000 | 1,500 | 4,000 | |

| II | 5,500 | 5,000 | 1,500 | 3,500 | |||||

| 400 | 350 | 2 | 4,110 | 3,420 | II-L | 4,500 | 4,000 | 1,5001) | 4,0001) |

| II | 5,000 | 4,500 | 1,5001) | 3,5001) | |||||

| 600 | 3 | 5,110 | 4,150 | II-L | 4,000 | 3,500 | 1,5001) | 3,5001) | |

| II | 5,000 | 4,500 | 1,5001) | 3,0001) | |||||

| 500 | 300 | 2 | 4,110 | 3,420 | II-L | 3,500 | 3,000 | – | 3,5001) |

| II | 4,500 | 4,000 | 3,5001) | ||||||

| 600 | 3 | 5,110 | 4,150 | II | 4,500 | 4,000 | 3,0001) | ||

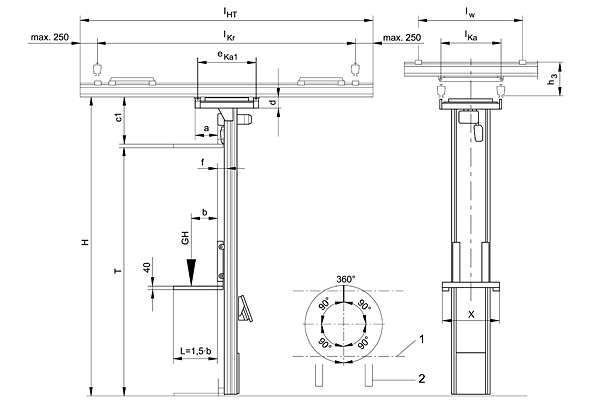

1) 2 x double trolley at each end of the crane for IHT > IKR + 240 mm. Dimension h3 increases by + 15mm.

b = Load centre distance

H = Unit height

T = Fork lifting height

IHT = Crane girder length

LKr = Crane span dimension

lw = Distance between supports

| Size |

Crab span dimension lKaand eKa1 [mm] |

Dimensions [mm] | Max. lifting speed [mm] | Weight for max. H [kg] | ||||

| Xmax | c | d | f 2) | f 2) | 300 | |||

| 2 | 800 | 1,000 | 650 | 160 | 135 | 135 | 8.0 | 400 |

| 3 | 1,000 | 1,000 | 650 | 80 | 80 | 85 | ||

| 920 | ||||||||

2) Dimension f for pivot centre

A KBK stacker crane mainly consists of a KBK double-girder suspension crane combined with a special stacker trolley and a load handling attachment.

A KBK stacker crane mainly consists of a KBK double-girder suspension crane combined with a special stacker trolley and a load handling attachment.